Here's the website URL https://www.wencerl.com. Wencerl is a leading service provider of

Close Mills: Multipurpose Tools for Specific Substance Removal

Sq. Finish Mills: Perfect for generating sharp corners and flat-bottomed cavities. - Ball Nose Stop Mills: Ideal for 3D contouring and sculpting elaborate surfaces.

Corner Radius Stop Mills : Combine the characteristics of square and ball nose mills for added strength and flexibility.Roughing Conclude Mills: Designed for rapid material elimination with minimum heat technology. Finishing Conclude Mills : Present easy finishes and limited tolerances in fragile operations.

Milling Instruments: Essential Elements for Effective Milling Functions

Confront Mills: Utilized for machining flat surfaces and generating a fine finish. Shell Mills: Multipurpose resources that could be useful for both of those roughing and finishing functions. Slab Mills : Appropriate for eradicating massive amounts of fabric from your workpiece.- Conclude Mills: Offer adaptability in chopping various products and shapes.

Fly Cutters: Offer a cost-productive Alternative for achieving a sleek surface end.

Instrument Holders: Guaranteeing Security and Precision in Machining

Collet Chucks: Provide high clamping power and are ideal for holding small-diameter equipment. Conclusion Mill Holders: Meant to securely maintain end mills and limit Software runout. Shell Mill Arbors : Accustomed to mount shell mills onto the machine spindle.Drill Chucks: Enable for brief alterations involving drills and other instruments. Speedy Alter Device Posts: Empower rapid Instrument alterations, lowering downtime in CNC functions.

Precision Reducing Applications: Acquiring Higher Accuracy in Machining

Carbide Instruments : Offer you excellent hardness and have on resistance for extended Resource daily life.Cermet Applications: Deliver outstanding surface area end and are ideal for large-pace machining. Significant-Velocity Steel (HSS) Resources: Adaptable and price-effective, appropriate for an array of apps. Ceramic Equipment: Effective at withstanding large temperatures and are used for challenging content machining. Polycrystalline Diamond (PCD) Tools: Offer Excellent have on resistance for machining non-ferrous supplies.

Threading Resources: Making Inner and External Threads with Precision

Thread Mills: Used for making internal and external threads with large accuracy. Faucet Drills: Deliver the correct hole dimensions for tapping operations. Die Heads: Allow for for speedy and specific thread chopping in guide operations. Threading Inserts: Replaceable chopping edges for successful thread generation. Chasers: Utilized in lathes for reducing threads on cylindrical workpieces.

Drilling Applications: Essential for Developing Holes in Various Supplies

- Twist Drills: Commonly employed for drilling holes in metallic, Wooden, and plastic.

Heart Drills: Used to produce a conical gap for precise centering from the workpiece. Phase Drills: Let for drilling many hole measurements without the need of switching applications. Spade Drills : Suitable for deep gap drilling with significant substance removing charges.Gun Drills : Created for precision drilling of deep holes with smaller diameters.

for cutting tools

Turning Tools: Shaping Components with Rotational Motion

Turning Inserts: Replaceable reducing edges for turning functions. Parting Tools: Utilized to Lower off sections of the workpiece for the duration of turning. Dull Bars: Permit for inside diameter machining with high precision. Grooving Equipment: Make grooves and slots inside the workpiece. - Knurling Applications: Make textured designs on cylindrical surfaces for improved grip.

Reducing Resource Products: Choosing the Suitable Product to the Work

Higher-Velocity Metal (HSS): Features good toughness and is suited to normal-objective machining. - Cemented Carbide: Presents substantial hardness and don resistance for prolonged Instrument lifestyle.

Cermet : Brings together ceramic and metallic resources for enhanced area complete.Ceramic : Able to withstanding large temperatures for machining tricky supplies.Polycrystalline Diamond (PCD): Presents Remarkable don resistance for non-ferrous content machining.

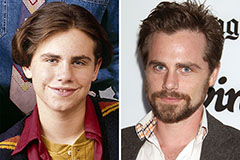

Rider Strong Then & Now!

Rider Strong Then & Now! Lark Voorhies Then & Now!

Lark Voorhies Then & Now! Andrew Keegan Then & Now!

Andrew Keegan Then & Now! Tina Majorino Then & Now!

Tina Majorino Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now!