Here is the web site URL https://www.wencerl.com. Wencerl is a leading company of

Conclusion Mills: Adaptable Equipment for Precise Product Elimination

Sq. Conclusion Mills: Perfect for generating sharp corners and flat-bottomed cavities. Ball Nose Conclude Mills: Perfect for 3D contouring and sculpting complicated surfaces. Corner Radius Conclude Mills: Incorporate the capabilities of square and ball nose mills for additional toughness and versatility. Roughing Close Mills: Made for immediate substance removing with minimum warmth generation. Finishing End Mills: Supply smooth finishes and limited tolerances in sensitive functions.

Milling Tools: Critical Factors for Economical Milling Functions

Experience Mills: Utilized for machining flat surfaces and manufacturing a good complete. Shell Mills: Adaptable instruments which can be utilized for both equally roughing and ending functions. Slab Mills: Appropriate for removing significant quantities of fabric through the workpiece. Close Mills : Supply adaptability in slicing many supplies and shapes.Fly Cutters: Give a Charge-helpful solution for achieving a sleek surface area finish.

Tool Holders: Guaranteeing Stability and Precision in Machining

Collet Chucks : Supply higher clamping drive and are perfect for Keeping compact-diameter resources.End Mill Holders: Designed to securely keep finish mills and lower Resource runout. - Shell Mill Arbors: Used to mount shell mills onto the equipment spindle.

Drill Chucks: Enable for speedy adjustments amongst drills as well as other instruments. Brief Transform Resource Posts: Permit fast Device alterations, reducing downtime in CNC operations.

Precision Slicing Resources: Attaining Significant Accuracy in Machining

Carbide Instruments : Offer you excellent hardness and have on resistance for prolonged Resource life.- Cermet Equipment: Deliver top-quality surface complete and are perfect for higher-pace machining.

Large-Velocity Metal (HSS) Tools: Versatile and price-effective, appropriate for a wide array of applications. Ceramic Resources: Capable of withstanding substantial temperatures and so are useful for hard content machining. Polycrystalline Diamond (PCD) Applications: Supply Outstanding use resistance for machining non-ferrous resources.

Threading Equipment: Building Inside and External Threads with Precision

- Thread Mills: Employed for generating internal and external threads with higher precision.

Tap Drills: Deliver the proper gap size for tapping functions. Die Heads : Allow for speedy and exact thread chopping in handbook operations.Threading Inserts : Replaceable slicing edges for productive thread creation.Chasers : Employed in lathes for chopping threads on cylindrical workpieces.

Drilling Instruments: Essential for Building Holes in Different Materials

Twist Drills: Generally used for drilling holes in steel, wood, and plastic. Center Drills: Made use of to produce a conical gap for precise centering of your workpiece. - Phase Drills: Allow for drilling multiple gap dimensions devoid of shifting resources.

- Spade Drills: Ideal for deep gap drilling with high materials removing rates.

Gun Drills: Made for precision drilling of deep holes with tiny diameters.

Turning Applications: Shaping Supplies with Rotational Motion

Turning Inserts : Replaceable slicing edges for turning functions.Parting Applications: Utilized to Reduce off sections of the workpiece during turning. Tedious Bars: Make it possible for for inner diameter machining with high precision. - Grooving Resources: Create grooves and slots in the workpiece.

Knurling Equipment : Generate textured patterns on cylindrical surfaces for improved grip.

Reducing Tool Resources: Picking out the Correct Content for that Task

- Higher-Speed Metal (HSS): Gives good toughness and is particularly suited to standard-objective machining.

Cemented Carbide: Offers high hardness and dress in resistance for extended Instrument lifestyle. Cermet : Brings together ceramic and metallic products for enhanced surface area finish.- Ceramic: Able to withstanding high temperatures for machining really hard resources.

Polycrystalline Diamond (PCD) : Gives Fantastic use resistance for non-ferrous product machining.

mill tool holder

Kel Mitchell Then & Now!

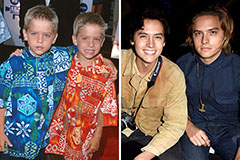

Kel Mitchell Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Hallie Eisenberg Then & Now!

Hallie Eisenberg Then & Now! Robert Downey Jr. Then & Now!

Robert Downey Jr. Then & Now! Lacey Chabert Then & Now!

Lacey Chabert Then & Now!