Here is the web site URL https://www.wencerl.com. Wencerl is a number one supplier of

Close Mills: Flexible Applications for Specific Product Removal

- Square Close Mills: Perfect for creating sharp corners and flat-bottomed cavities.

Ball Nose End Mills: Ideal for 3D contouring and sculpting intricate surfaces. Corner Radius Conclude Mills: Incorporate the features of sq. and ball nose mills for extra toughness and versatility. Roughing End Mills: Made for swift materials removal with small warmth era. Ending Close Mills: Supply clean finishes and restricted tolerances in delicate operations.

Milling Equipment: Vital Elements for Productive Milling Functions

Face Mills : Used for machining flat surfaces and creating a great end.Shell Mills: Versatile applications that may be used for equally roughing and finishing operations. Slab Mills: Suitable for taking away huge amounts of material from your workpiece. - Finish Mills: Supply adaptability in slicing a variety of resources and styles.

- Fly Cutters: Offer a Price-productive Remedy for reaching a sleek surface area end.

Resource Holders: Making sure Stability and Precision in Machining

Collet Chucks : Present superior clamping drive and are perfect for Keeping little-diameter resources.Stop Mill Holders: Built to securely keep conclude mills and minimize Software runout. Shell Mill Arbors : Accustomed to mount shell mills onto the machine spindle.- Drill Chucks: Allow for swift alterations between drills and other applications.

Brief Change Device Posts: Enable rapid Resource alterations, lowering downtime in CNC functions.

Precision Reducing Instruments: Attaining Large Accuracy in Machining

Carbide Equipment : Supply exceptional hardness and use resistance for extended tool lifestyle.Cermet Tools : Supply exceptional floor complete and are ideal for superior-velocity machining.High-Velocity Steel (HSS) Equipment: Multipurpose and value-successful, appropriate for an array of applications. Ceramic Equipment: Able to withstanding higher temperatures and so are used for challenging materials machining. Polycrystalline Diamond (PCD) Resources: Give exceptional put on resistance for machining non-ferrous components.

turning inserts

Threading Applications: Developing Internal and Exterior Threads with Precision

Thread Mills: Utilized for developing inside and external threads with higher accuracy. Faucet Drills: Offer the proper gap sizing for tapping operations. Die Heads: Allow for quick and exact thread slicing in manual functions. - Threading Inserts: Replaceable cutting edges for effective thread generation.

Chasers: Used in lathes for reducing threads on cylindrical workpieces.

Drilling Equipment: Important for Producing Holes in Many Supplies

- Twist Drills: Frequently useful for drilling holes in steel, wood, and plastic.

Middle Drills: Employed to create a conical gap for correct centering of the workpiece. Phase Drills: Enable for drilling numerous gap measurements without the need of switching equipment. Spade Drills : Suitable for deep gap drilling with higher substance removing premiums.Gun Drills: Suitable for precision drilling of deep holes with little diameters.

Turning Resources: Shaping Materials with Rotational Movement

Turning Inserts : Replaceable slicing edges for turning operations.Parting Applications: Used to Lower off sections of a workpiece all through turning. - Dull Bars: Allow for for internal diameter machining with substantial precision.

Grooving Resources: Make grooves and slots during the workpiece. Knurling Instruments: Develop textured patterns on cylindrical surfaces for enhanced grip.

Cutting Device Supplies: Selecting the Right Substance for your Task

Significant-Speed Metal (HSS): Features good toughness which is well suited for typical-intent machining. Cemented Carbide : Gives substantial hardness and use resistance for prolonged Software lifestyle.Cermet: Brings together ceramic and metallic products for enhanced surface end. - Ceramic: Effective at withstanding significant temperatures for machining difficult components.

Polycrystalline Diamond (PCD): Offers Fantastic dress in resistance for non-ferrous content machining.

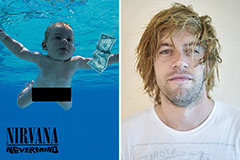

Spencer Elden Then & Now!

Spencer Elden Then & Now! Alana "Honey Boo Boo" Thompson Then & Now!

Alana "Honey Boo Boo" Thompson Then & Now! Lark Voorhies Then & Now!

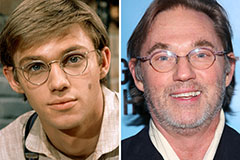

Lark Voorhies Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Bernadette Peters Then & Now!

Bernadette Peters Then & Now!