Here is the web site URL https://www.wencerl.com. Wencerl is a number one service provider of

End Mills: Versatile Instruments for Specific Material Removing

Sq. Conclude Mills : Perfect for generating sharp corners and flat-bottomed cavities.Ball Nose Close Mills: Great for 3D contouring and sculpting complex surfaces. Corner Radius Stop Mills: Incorporate the attributes of sq. and ball nose mills for added strength and flexibility. - Roughing Stop Mills: Designed for rapid material removal with small warmth era.

Ending Conclusion Mills : Deliver easy finishes and restricted tolerances in sensitive operations.

Milling Instruments: Necessary Elements for Effective Milling Operations

Encounter Mills: Used for machining flat surfaces and producing a wonderful complete. Shell Mills: Versatile instruments that can be useful for the two roughing and ending functions. Slab Mills: Suited to getting rid of large quantities of material with the workpiece. - End Mills: Offer you flexibility in slicing many components and designs.

Fly Cutters : Provide a cost-powerful Resolution for achieving a clean floor complete.

Device Holders: Making certain Security and Precision in Machining

Collet Chucks: Offer superior clamping power and are perfect for Keeping tiny-diameter resources. Close Mill Holders: Built to securely hold end mills and reduce Instrument runout. - Shell Mill Arbors: Utilized to mount shell mills on to the machine spindle.

- Drill Chucks: Let for swift alterations involving drills as well as other instruments.

Fast Change Tool Posts: Help swift Device adjustments, decreasing downtime in CNC functions.

Precision Cutting Applications: Attaining Large Precision in Machining

- Carbide Tools: Provide great hardness and wear resistance for extended Resource lifestyle.

Cermet Resources : Provide outstanding surface area end and are perfect for higher-pace machining.Significant-Pace Metal (HSS) Equipment : Functional and value-powerful, well suited for a wide range of programs.Ceramic Tools: Able to withstanding high temperatures and therefore are utilized for difficult content machining. - Polycrystalline Diamond (PCD) Tools: Offer Excellent don resistance for machining non-ferrous elements.

Threading Tools: Building Internal and External Threads with Precision

Thread Mills: Utilized for making interior and external threads with substantial accuracy. Tap Drills : Deliver the proper gap sizing for tapping operations.Die Heads: Enable for speedy and precise thread cutting in guide functions. Threading Inserts: Replaceable chopping edges for successful thread generation. Chasers: Utilized in lathes for cutting threads on cylindrical workpieces.

Drilling Equipment: Important for Generating Holes in Various Supplies

Twist Drills : Usually used for drilling holes in metal, wood, and plastic.Center Drills: Applied to create a conical gap for exact centering in the workpiece. Move Drills: Permit for drilling various hole dimensions without having altering resources. - Spade Drills: Ideal for deep hole drilling with superior substance removing rates.

- Gun Drills: Designed for precision drilling of deep holes with compact diameters.

Turning Tools: Shaping Products with Rotational Movement

- Turning Inserts: Replaceable chopping edges for turning functions.

Parting Applications: Utilized to Slash off sections of the workpiece all through turning. Tedious Bars: Permit for inside diameter machining with significant precision. Grooving Equipment : Generate grooves and slots while in the workpiece.- Knurling Applications: Create textured styles on cylindrical surfaces for improved grip.

Slicing Device Elements: Picking out the Suitable Materials with the Position

Superior-Velocity Steel (HSS): Delivers very good toughness and is suited to common-goal machining. Cemented Carbide : Offers higher hardness and use resistance for extended Resource lifestyle.- Cermet: Combines ceramic and metallic elements for enhanced surface area complete.

Ceramic : Able to withstanding superior temperatures for machining tricky products.Polycrystalline Diamond (PCD): Gives Remarkable don resistance for non-ferrous content machining.

slotting mill cutter

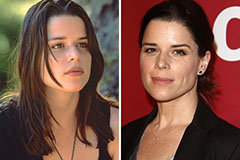

Neve Campbell Then & Now!

Neve Campbell Then & Now! Loni Anderson Then & Now!

Loni Anderson Then & Now! Karyn Parsons Then & Now!

Karyn Parsons Then & Now! Robbie Rist Then & Now!

Robbie Rist Then & Now! Dolly Parton Then & Now!

Dolly Parton Then & Now!